The flickering fire in the fireplace creates an atmosphere of coziness and comfort in a country house. The hearth looks especially presentable when made of brick. But, if for some reason it cannot be installed, a metal fireplace will be a good alternative. He copes with the task of heating no worse than a brick counterpart.

The advantage of metal fireplaces

A metal stove fireplace is considered an excellent replacement for a brick heating unit. Its heat transfer will be enough to provide heat to one of the rooms in the house. Even in the coldest weather, it will warm everyone in the room.

The metal fireplace can be made in the form of a stylish and original design, which easily fits into the elegant interior. By the way, the Japanese invented metal stoves, and they are well versed in the design of premises for various purposes.

Among the advantages of foci of this type, their portability and lightness should be noted. They can be mounted, moved or disassembled without any problems. The weight of the stove - a fireplace made of metal is much less than that of a stone counterpart, it does not need to equip a solid, heavy and expensive foundation.

Ease of operation is combined with a high rate of efficiency. To melt it, requires a small amount of firewood. It takes a little time and solid fuel to warm up, since the metal heats up much faster than bricks and at the same time it gives off so much thermal energy that it is enough to warm itself in the cold.

As for the shortcomings, they are few in metal aggregates. The main one is the quick cooling of the structure after the completion of the combustion process. Also, one should not forget about the high fire hazard of these foci.

If you accidentally touch a metal fireplace on wood during fuel loading, serious burns can occur. Therefore, in this case, use tight gloves.

Installation location

It is permissible to mount a metal hearth almost anywhere in the room, if desired even in the center. But such a location will lose in terms of aesthetics and will not comply with fire regulations, since the structure can be easily touched and knocked over.

The best solution is to install a metal wood fireplace near the wall of the room, you can build the structure into it, which will save square meters of area. In this case, the chimney is neatly laid along the wall, and it will not be difficult to bring it out onto the street.

This option of placing the hearth will prevent smoke from the air in the room. True, the wall behind it will not be clean - it will become smoky and blacken. The fireplace can be placed near the wall, stepping back from it a short distance.

In this case, if necessary, it will be easy to move from one wall to another. It is also easier to care for, since the structure is movable. A firewall is attached to such a fireplace, but even it will not be able to protect the walls from damage to the whitewashed and painted surface, darkening of wallpaper.

In addition, a metal fireplace can be placed in the corner of the room, which is now considered a stylish option. In this case, it takes up less space: the room visually seems more spacious, since the living space is not rebooted.

The commercially available designer models of corner fireplaces stand out for their originality. They usually have small parameters and are resistant. They are much easier to heat and then clean. The chimney is not difficult to bring out.

Experts do not recommend installing metal fireplaces for homes close to doors or windows. The fact is that air sources adversely affect the efficiency of the heating unit.

So, experts recommend the following options for placing fireplaces made of metal:

- built into the outer wall,

- wall mounted

- angular,

- located separately.

DIY materials for making a fireplace made of metal

For example, a fireplace from a barrel that was previously used is considered very simple to manufacture. This does not require large material costs.

But to assemble a stove from sheets of metal, you need to prepare:

- for the fuel compartment - metal sheets having a thickness of 3-5 mm,

- for an ashpit - sheets of metal 0.5 mm thick,

- grate or for its manufacture of reinforcing bars,

- a door made of refractory glass or cast iron (for more details: "Which glass doors for a fireplace are better to choose - varieties, advantages and disadvantages of doors with glass"),

- door hinges,

- for legs - metal rails with a diameter of 5 centimeters or more,

- for a pedestal - several sheets of chipboard or a cement slab, or bricks,

- for mortar - cement,

- basalt cotton wool

- for a chimney - pipe products with a diameter of at least 20 centimeters and, if necessary, a bend for the outlet and connection of pipes,

- mounting brackets

- fungus, head,

- heat resistant sealant,

- grinder

- welding

- measuring tool,

- screwdriver.

Installation diagram of an iron fireplace stove

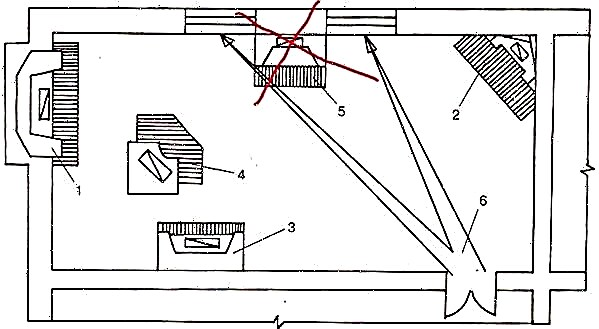

You can use ready-made schemes or hand-made drawings of a metal fireplace. At the same time, they should depict the source itself and its details, designate the parameters and think over the assembly sequence in the form of numbers or arrows.

It is necessary to begin installation with a pedestal, and to complete the removal of chimneys outside the roof. When making a drawing, one must not forget about the features of the layout of rooms, about ceiling and floor floors, flooring.

The main stages of installation

Making a stove - a fireplace from metal with your own hands is not difficult. Even a novice craftsman is able to cope with this task, subject to the availability of competently drawn up drawings and compliance with the technology of the work.

Installation is carried out in stages:

- Since the fireplace made of steel or other metal heats up quite strongly, before installing it, first prepare the floor surface. When the floor is wooden, then experts recommend laying a heat-insulating layer of basalt wool between it and the ceiling.

- Then you should prepare the pedestal. For its manufacture, you can use several sheets of chipboard, connecting them together. A refractory coating of fiber cement board or ceramic tile is laid on top.

- In the event that the walls were wallpaper or finished with other materials that are subject to burning, it is advisable to protect the installation area of a metal fireplace with brickwork, ceramic tiles or artificial stone.

- When the preparation of the premises is completed, proceed to the assembly of the heating structure. The device of the fireplace is not complicated. First of all, the side walls of the fireplace are connected by welding. A back wall and a front wall are welded to them, in which a hole is used to pre-cut a hole in the middle for loading firewood, and in the bottom in an ash drawer for cleaning ash.

- Using welding, a thick sheet of iron is attached to the side walls as the bottom of the unit. Before this, legs are attached to it, the maximum height of which is 10 - 12 centimeters, and the width is not less than 5 - 7 centimeters. Since a homemade metal fireplace requires stability, the dimensions of the supporting elements depend on the weight of the structure. After mounting the legs, the body assembly is completed.

- Next, install partitions for the combustion chamber and the ash pan. It is better to make a firebox two-layer. To do this, it is equipped with a separate chamber inside the unit, as a result of which it turns out to be isolated from the furnace walls.

- Between the ash pan and the firebox mount a grate, which can be purchased or made independently from reinforcing bars.

- Hinges are welded to the oven to install the door. Below the furnace opening, by about 10 centimeters, by welding, the corners are fixed, which will be the basis for the grate.

- From above, a metal fireplace with their own hands is closed with a wall-cover. When there is no hole for the chimney in it, then it is cut out before installing the top.

- At the very end proceed with the installation of the chimney.

In the process of assembling the fireplace after the completion of the next stage, it is necessary to check the correctness of the construction with the building level. The presence of gaps in it indicates that the elements were connected unevenly and the oven needs to be re-done.

Arrangement of a chimney for an iron fireplace

The chimney is an important part of the heating structure. It takes combustion products, including smoke, out of the residential building. No hearth can function without it.

The chimney for a fireplace made of iron certainly consists of a long pipe or several pipes connected in series. He is taken out through the roof.

- Direct. In this case, one pipe is directed upward vertically until it reaches the roof.

- Two to three knee. The chimney is removed in a zigzag fashion.

Pipes for smoke extraction are inserted into the hole on the top surface of the unit, and with the help of brackets they are led parallel to the wall with support on it up to the roof.

To remove the chimney, make bends and use several pipes that join together using elbows. All joints are treated with heat-resistant sealant. Basalt wool is usually used for thermal insulation.

As a result, the chimney is led to the roof. He is made towering on her ridge no less than 50 centimeters. A cap and fungus are placed on top of the pipe to protect the chimney from atmospheric precipitation.

Fireplaces are not recommended to be painted, since such a coating can melt or crumble, which will spoil the appearance of the heating structure.

Maintenance and care of the iron hearth

For fireplaces with a metal firebox to serve for a long time, they require proper care. First of all, once every 2 weeks they are dry cleaned: residual ash is removed from the ash pan and the soot chamber is cleaned of soot. You also need to regularly clean the chimney.

Metal is easily susceptible to corrosive processes, so a fireplace made from it cannot be washed with water. You can only wipe the glass doors and the surface of the chimney pipes with a damp cloth from dust accumulated on them.

It is also important to follow the operating rules. After the assembly of the fireplace is completed, they wait about a month and only then they begin to heat it. During this period, he will have time to dry out, and the sealant will better set.

Equally important is the right choice of solid fuel. It is preferable to heat the birch logs, as they emit 20% more heat. Ethanol and pellets can also be used as fuel.

To use the iron fireplace was comfortable, you need to remember a few rules:

- The design should not be installed in the active zone of the family's life - in the kitchen, in the middle of the room, etc., since it can be easily touched and knocked over. It is advisable to install a fireplace in a corner or near the far wall of the room.

- Do not mount the hearth near flammable materials, windows and furniture.

- The unit is not allowed to be left unattended; children should not be allowed to approach it.

- The fireplace must be protected from walls and floors made of wood materials.

- Flammable substances are not stored near the outbreak.

Subject to the above rules, the fireplace will last for many years, warming the house with heat.