The box from the array has the following advantages:

- low thermal conductivity

- high strength and frost resistance,

- durability,

- environmental friendliness

- the opportunity to implement various design ideas.

At the same time, a wooden canvas has the following features:

- untreated raw materials quickly absorb moisture,

- the presence of cracks and knots,

- flammability.

To reduce absorption, the board is dried, treated with hot steam and impregnation.

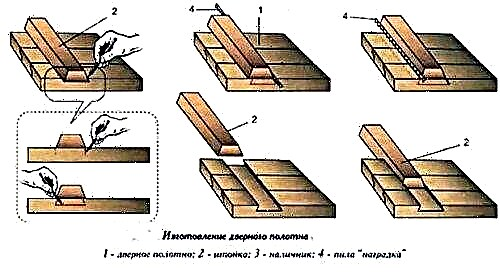

Massive doors

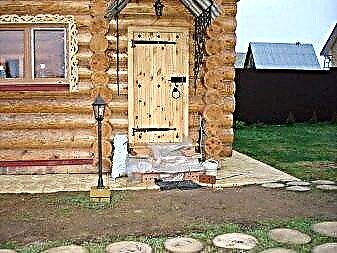

Before the manufacture of wooden doors, it is recommended to determine the features of the production process. The dacha can be protected from robbers by a massive sheet, for the manufacture of which thick sheet pile or planed boards are used. The resulting design is strengthened by horizontal or inclined jumpers.

To make a massive door, a tree of dense structure is used

For the manufacture of a massive entrance door, use cedar, larch or oak. Such wood is characterized by a dense structure and textured pattern.

If the design of the summer cottage includes a bathhouse, then linden and pine are used to equip the opening. The bath should be operated after processing wood with an antiseptic.

Panel doors

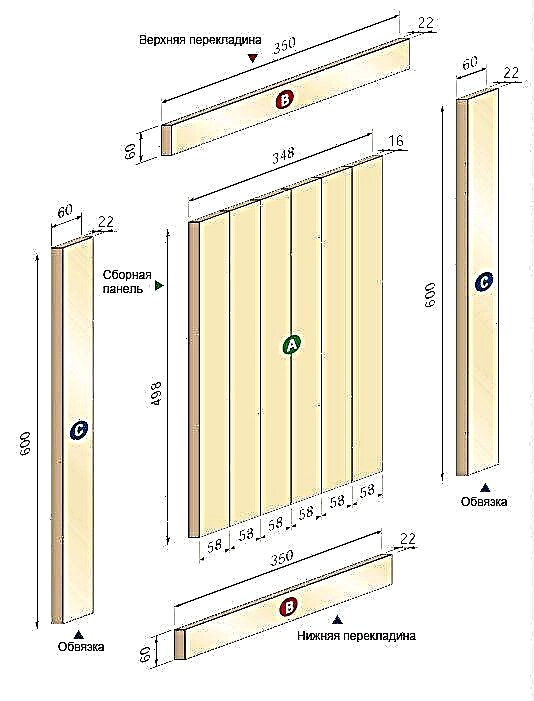

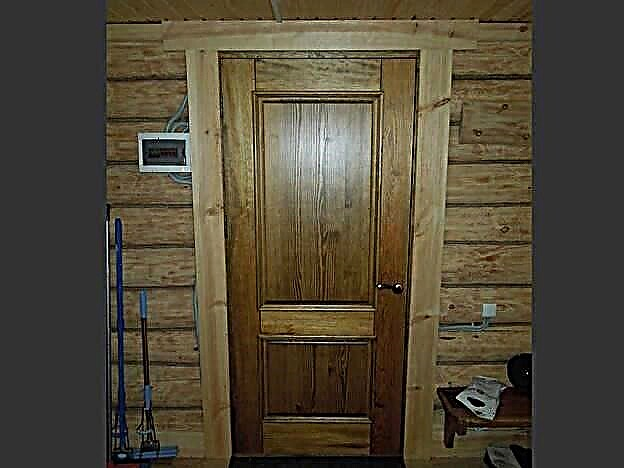

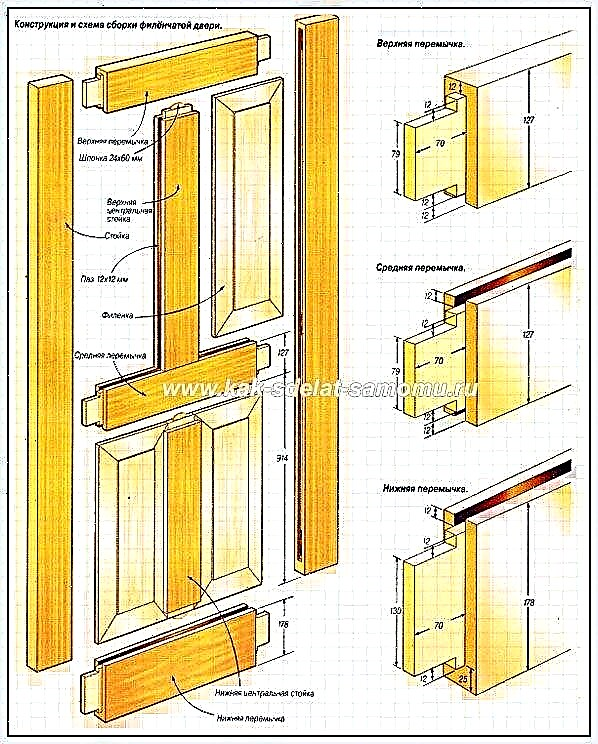

For the manufacture of paneling, boards and beams obtained by gluing lamellas are used. Then the workpiece is covered with veneer. Before you build the canvas, a drawing is prepared. It indicates the configuration of the panels. It can be the same or different. Instead of wooden elements, you can use glass.

Paneled doors are most often installed indoors

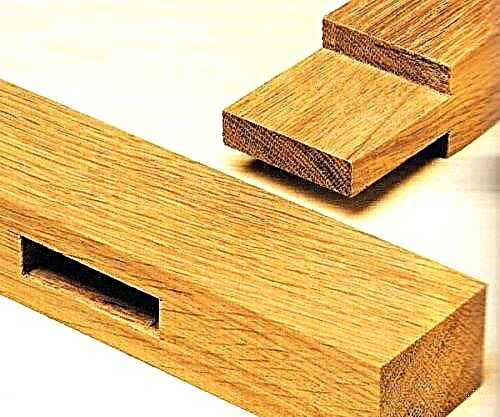

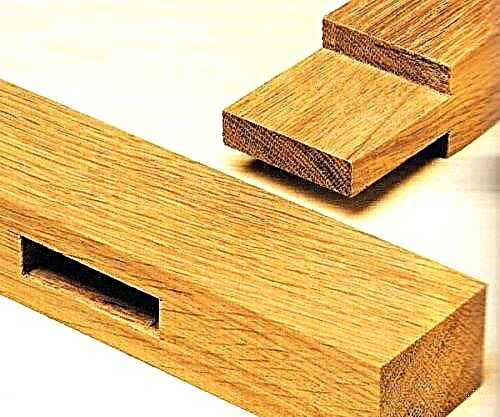

To equip the vertical and transverse elements, you will need to glue the beam. For the manufacture of the canvas, a floorboard of the appropriate thickness is used. Spikes are used to fix individual elements.

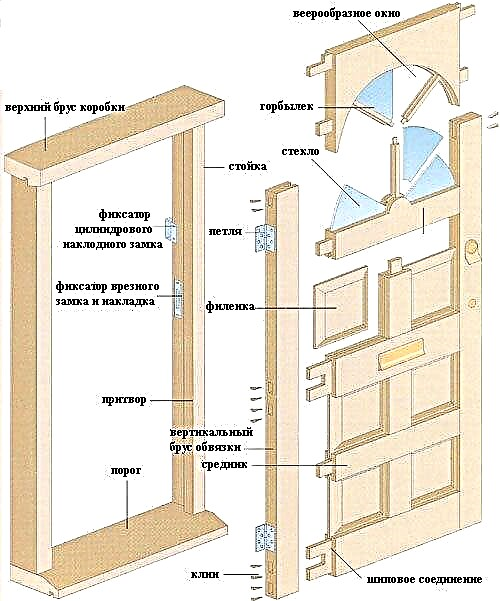

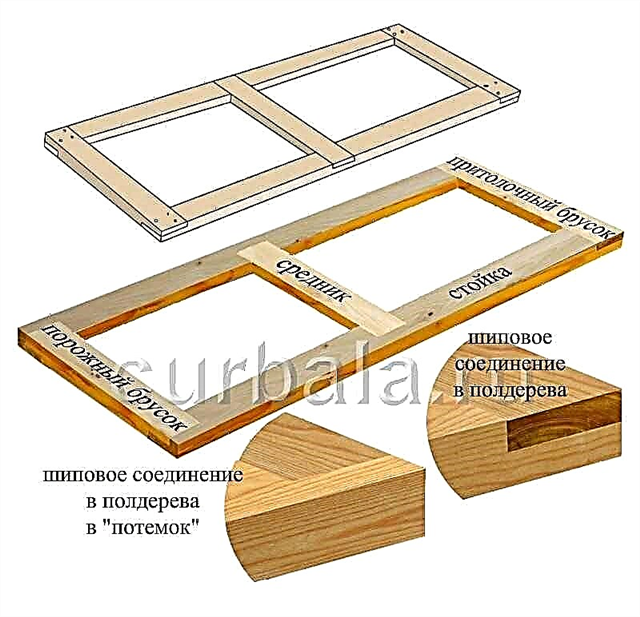

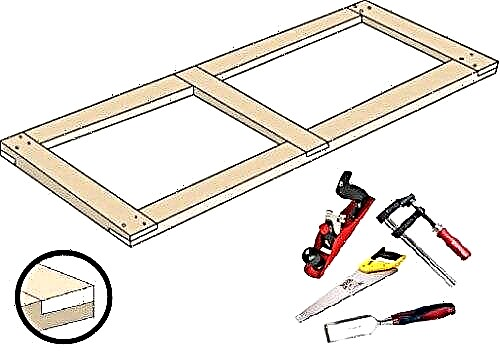

Door assembly diagram

If a panel is used to make the canvas, you need to consider:

- the reliability of the product is directly affected by the number of transverse

- a home-made box is formed from a bar, and a rail or plastic is used to make the panel,

- glazing bead is used to fix the panels.

Since the panel door is small in thickness, it is considered the best option to equip the interior doorway.

Panel doors

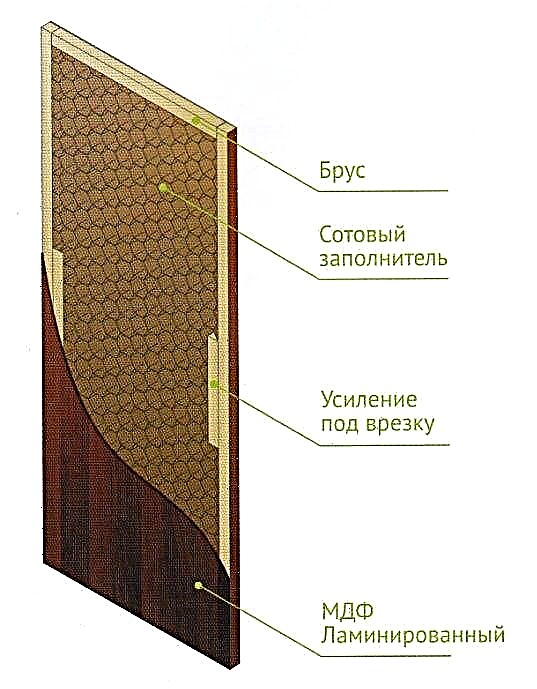

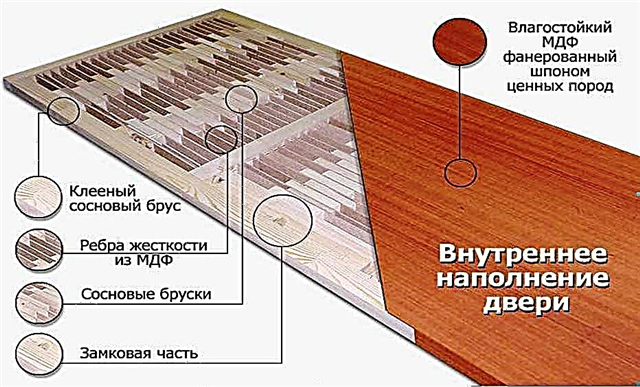

The panel box is made of fiberboard, veneer or laminate. The frame is assembled from boards. As a shield, sheets of fiberboard, MDF or chipboard are used.

Panel door design

Considered canvases are classified into the following types:

- solid - are filled with bars fastened together,

- hollow - are made of side and transverse bars. Lining is used for cladding,

- shallow - have different filling.

To independently create a high-quality canvas, the frame is pre-coated with glued plywood. The material is laid in 2 layers. The size of 1 layer is 24 mm. This technology prevents deformation of the coating..

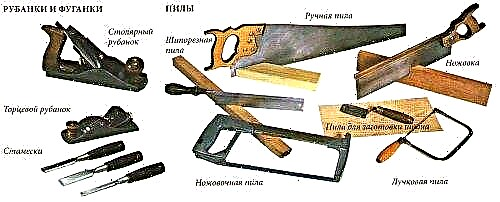

Tools for work

From the tools you will need:

- to create grooves and holes, you will need a milling cutter,

- hacksaw,

- to polish the ends of the doors, you need a planer,

- chisels

- hammer,

- screwdriver.

Standard door kit

To assemble the doors you will need the following materials:

Acquired wood is additionally dried. Boards are laid so that they do not touch each other.

Lumber selection

Before assembling the canvas, an individual plan of upcoming work is drawn up. Particular attention is paid to the selection of boards. The following criteria are taken into account:

- financial opportunities,

- acquisition of “commercial timber,

- residual humidity - 15%,

- checking the evenness of the material,

- thickness of boards - 25-50 mm,

- the array is polished.

Step-by-step manufacturing instructions

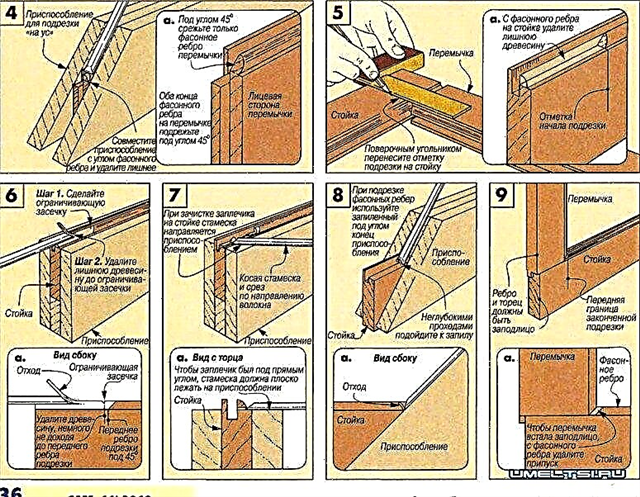

Any phased plan for the manufacture of the door involves the assembly of the shield. If installation of a cloth in a bath is provided, then simple assembly of a board is carried out. To fix the boards, transverse and longitudinal elements are used. A warm box for the home is made taking into account aesthetics. The assembled shield is ground.

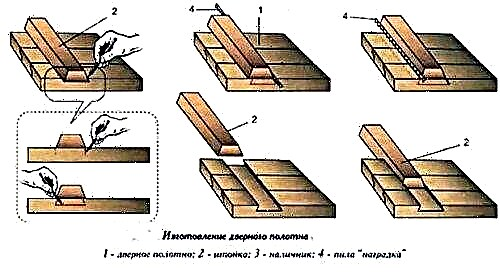

Making a door from solid wood

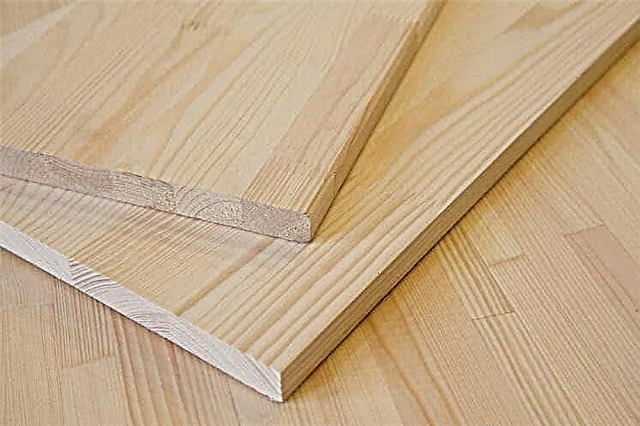

The step-by-step plan for assembling the web includes the right choice of consumables. To make a shield, grooved boards with a thickness of more than 25 mm will be required. Then the consumable is sawn into pieces.

The tongue and groove boards should be flat and without grooves on the front sides

When assembling the shield, it is recommended to take into account the direction of the annual rings. To connect the tongue-and-groove boards, a thorn-groove lock and wood glue are used. If the consumables are non-grooved boards, then they are collected with glue.

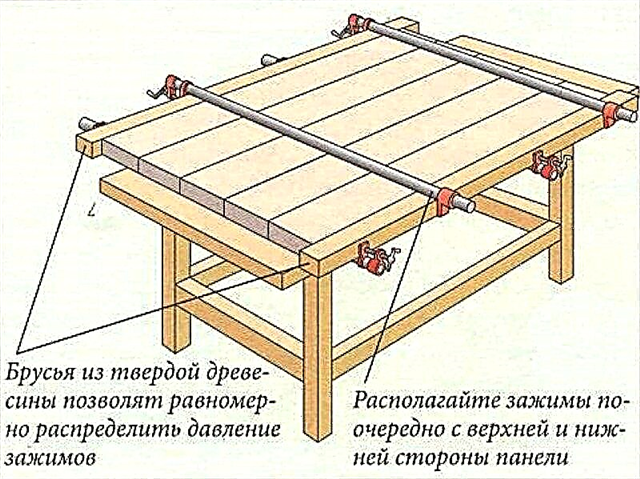

Work is carried out on the surface of a large area. The collected coating is tightened with clamps. If the shield is dry, it is milled. In order to have good sound insulation, it is recommended to assemble a shield from several layers of boards. The resulting structure is clamped with clamps.

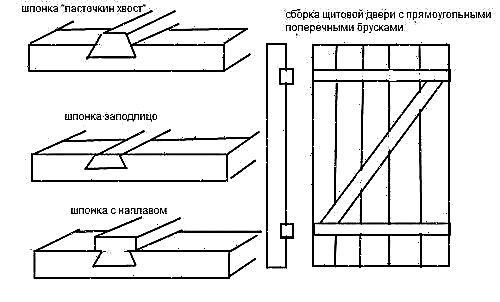

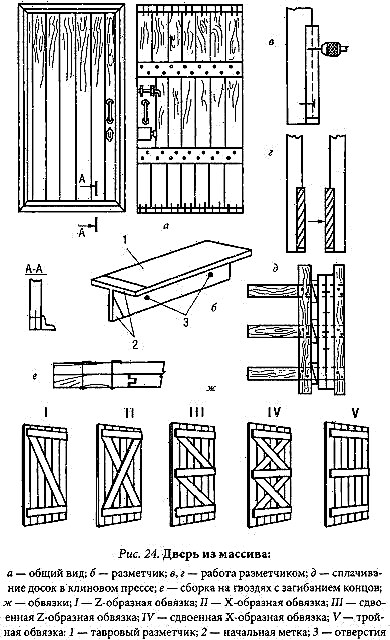

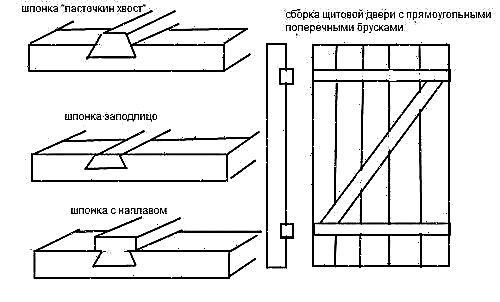

Traditional methods of dressing boards in solid wood doors

For strapping, the cross members installed at the top, in the middle and at the bottom of the cover are used. Marking for grooves is performed on the canvas. The recesses to be made should be ½ of the thickness of the consumable.

Using a milling cutter holes. It is more difficult to cut the grooves manually. This will require a chisel. A rubber mallet is used to insert the cross member. If it is planned to apply a drawing to the resulting shield, then its outline according to the template is circled in advance. A cutter is used for cutting.

Cut-outs are milled according to a pre-applied pencil drawing.

Then the painting is carried out with pre-treatment with an antiseptic. On the canvas and the box make markings for the installation of loops. The marking for the handle and the lock is similarly performed. The last stage is the canopy of the canvas into the opening.

Antiseptic and varnish treatment

Panel door manufacturing

Instructions for the manufacture of thyroid tissue allows the use of finely filled boards. Specialists distinguish 3 methods of assembly of such a design:

- preliminary assembly of the frame with the subsequent filling of its internal space. Using this technology, you can create a solid or finely filled shield,

- separate manufacture of the shield with its subsequent fixation in the frame. The last stage is lining with finishing material,

- the manufactured shield is mounted in the frame, faced.

To assemble the canvas according to the first technique, primary strapping is carried out. She will determine the size of the future door. For the construction, a bar with a section of 30 × 120 mm is used. Consumables are cut according to the dimensions of the future design.

The next step is to select the type of connection in the corners. Experts advise using the "half tree" method. Accurate marking of future grooves is an important stage in the assembly of the shield.

Wireframe connection diagram

All grooves are coated with glue. The joining of the beam is carried out on a flat but large area. If the glue has dried, the joints are fixed with pins. For this, through holes with a diameter of 8-10 mm are made..

For facing the frame, plywood or fiberboard is used. The marking is carried out, the frame is removed. The frame is returning to its original place. It must be pressed to the facing material treated with glue.

For facing, plywood or fiberboard is used.

To fill the internal space, MDF is used. It is glued to the bottom sheet of finishing material. But first the glue should dry well. In parallel, it is recommended to prepare consumables for the outer cladding of the canvas.

Internal filling gives the web rigidity

If you need to glue 2 sheets, then the first sheet is fiberboard, and the second is laminated material or shf. The resulting design is sent under the press.

It is possible to sheathe the door with natural wooden battens. They are fixed to the frame. The holes made are filled with a mixture of glue and sawdust. If the surface has dried, it is treated with sandpaper. All corners and ends are processed by a mill. A handle and a lock cut into the finished door leaf, hinges are fixed. The door is mounted in the appropriate box.

Using a similar technique, a frame door is made - the internal space is additionally strengthened by beams. But before starting work, accurate calculations are carried out, a drawing is prepared.

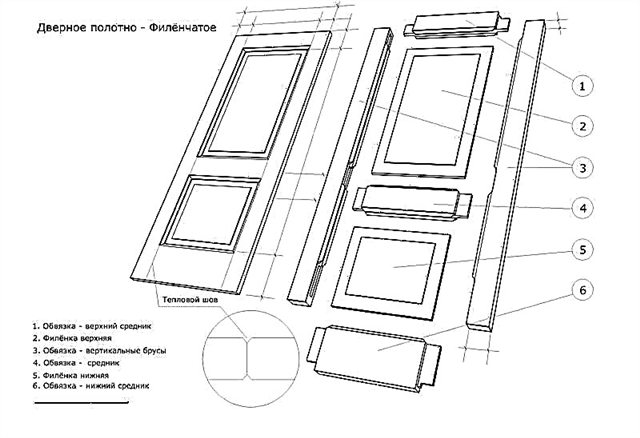

Panel door manufacturing

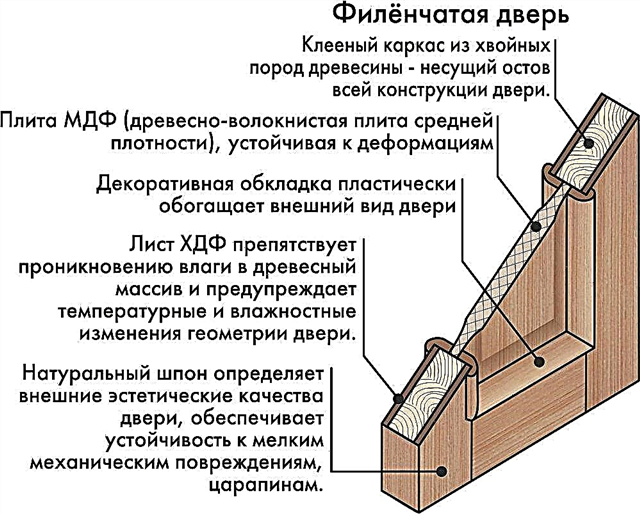

To make a panel door, you will need special carpentry tools and experience. The structural components are made of plywood, massive boards. A drawing is prepared in advance, on which 4 panels are marked.

Section pane door

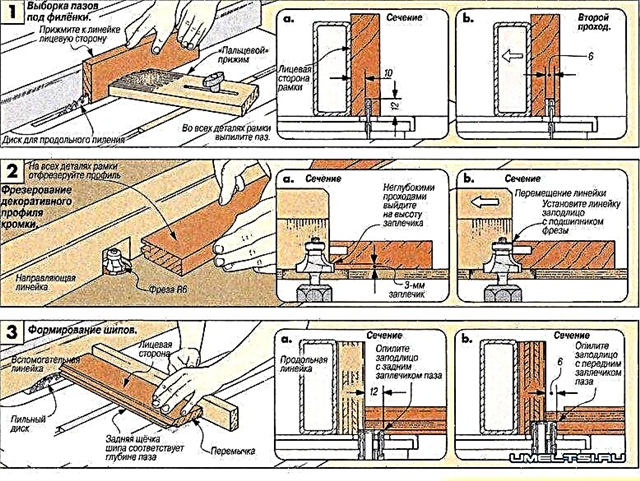

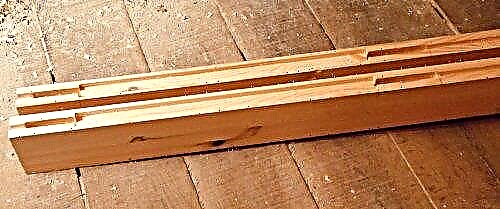

The frame is made of timber. It is pre-treated with a mill. Then a groove is made on one side of it. Spikes are cut on the crossbars, and the edges are milled. In the grooves, insert panels and mediators.

Panel door assembly diagram

The end part of the coating, which will go to the end of the canvas, should be flat. In vertical elements, slots are made to assemble the structure.

To make panels, plywood or chipboard is used. Some panel elements are replaced by glass. In this case, glazing beads are additionally used. Panels with a flat plane are mounted and framed with a glazing bead.

Otherwise, the panels are milled. In this way, a relief configuration is created. Plywood is used for the manufacture of panels. Each element of the future canvas is treated with an antiseptic, dried.

Milling Scheme 2

All parts are assembled in a single design on a flat surface, and each spike is coated with special glue. Step-by-step door assembly:

- gluing the cross members into the grooves of the vertical bars,

- installation of middle men,

- installation of the remaining panels,

- gluing a vertical beam,

- fixing glazing beads for decoration.

To install the spikes into the grooves, a rubberized hammer is used. The canvas is lined on the sides. A corner is used to check the corners. The coating is compressed by clamps.

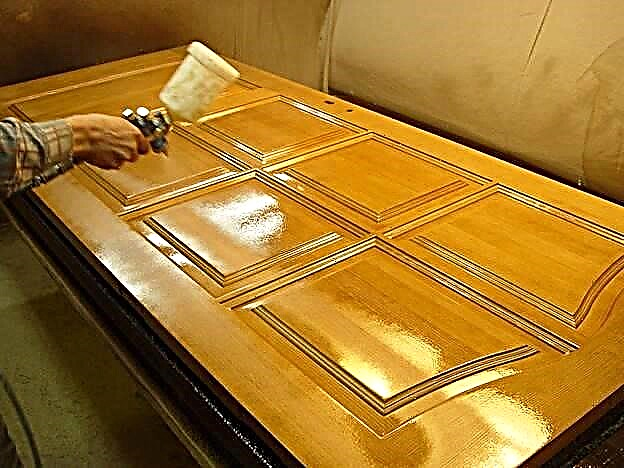

On the canvas, markings are made for installing loops and handles with a lock. Fittings are installed after finishing work. Acrylic paint or varnish is used for finishing. To get a dark coating, stain is used.

Warming and sound insulation

For carrying out thermal insulation works, a heater is used. With its help, that part of the canvas that is covered with fiberboard is glued. If the foam gets out of the frame, it is cut with a knife. Finishing material is fixed on top - fabric or leatherette. A stapler is used to fix the material. Read more about this in the article “How to insulate an entrance wooden door”.

Door insulation scheme

Painting

The next step is the processing and decoration of the manufactured structure. It is recommended to adhere to the following plan:

- sanding or sanding machine coating treatment,

- wood impregnation with an antiseptic. The first layer should dry well. Then the processing is repeated,

- the canvas is covered with special putty, which can be replaced with a primer. In this case, the canvas is processed 2 times. But each applied layer should dry well. This will take about 2 days,

- paint, varnish, stain are used to finish the coating. The stain should be applied to the primer. Given the desired shade, the appropriate number of stains is applied. It will take 4 hours to dry each coat. To fix the result, the stain is covered with two layers of varnish.

For finishing the door, paint, varnish, stain are used.

Experts advise to process the door with special protective agents against moisture and pests.. If the door leaf will be installed in the apartment, then it is covered with flame retardant. To perform a more complex version of the scenery, you will need the help of a specialist. Read more about painting and processing the door in the article “Painting wooden doors“.

Korovin Sergey Dmitrievich

Master of Architecture, graduated from Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

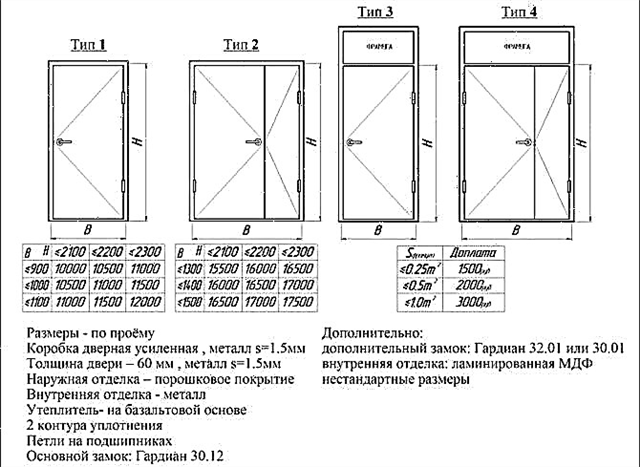

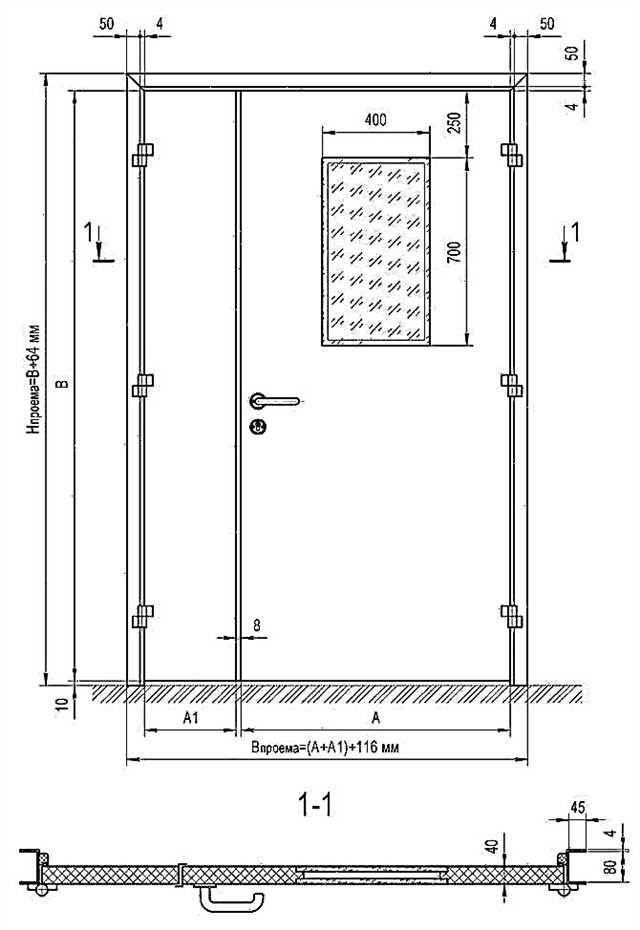

Metal entrance doors - constructive

In a typical embodiment, a metal door consists of a box, web, hinges and mounting elements (plates, eyes, pins). You can’t do without certain costs for materials and components, but a self-made door will cost much cheaper than the purchased one. The exact list of consumables depends on the design, size and purpose - if the simplest frame with sheathing and lintel is enough for the hosblock, then the door must be multilayered with effective locking hardware and decorative lining to enter the house. In the second case, an approximate set of necessary is as follows:

- A metal corner (from 5 mm) or a profile - for a box,

- Metal corner or profile pipe - for the frame, stiffeners,

- Sheet metal - for power sheathing (optimal thickness 2-3 mm).

- Thermal insulation material (mineral wool, polystyrene, EPS, or PSB),

- Accessories - hinges (preferably with bearings), gasket, peephole, lock / locks, handle, etc.,

- Finishing - wood, forging, plastic (for the inside there are various panels or laminate).

One of the most important stages is measurements, if you make a mistake, the installation of the door will become much more complicated in the future, so you should adhere to certain recommendations:

- All measurements are not from the finishing layer, but from the draft wall,

- There should be a groove between the box and the opening, standard - 2 cm (for alignment and mounting seam),

- The gap between the box and the web on the hinge side is 3 mm, on the lock side 5 mm.

The presence of a working drawing with dimensions or at least a sketch will be a good help, not every fantasy is developed enough to imagine the final result in the mind. Fortunately, there are enough workable drawings on the Web, if there are also difficulties with drawing and drawing.

Preparation stage

Begin work by dismantling the old door and completely clearing the opening. Only after a thorough examination of the condition of the base can we conclude whether it is suitable for installing metal structures or not. You may have to narrow it (expand) in accordance with the required dimensions, further strengthen it. The latter is typical for buildings made of cellular concrete, wood, as well as other materials with a significant degree of deterioration. Therefore, the necessary technological operations are carried out.

After receiving the passage in the wall with the correct geometry, you can proceed with the production of measurements. Based on this, a drawing of a metal door is developed. In addition to determining the dimensions of the frame and sash, you should choose the design scheme. First of all, in which direction it is more convenient to open the canvas, where it is better to install locks, hinges (their number) and fittings (handle, eye) on it. Sometimes it is advisable to make a variant of "one and a half". In it, a small sash is rigidly fixed, but if necessary, temporarily expand the opening (for example, when moving bulky goods) it is easy to swing it open.

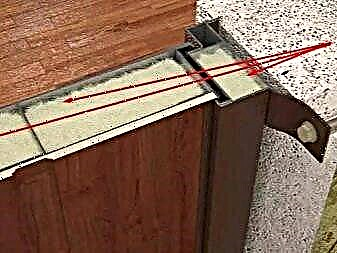

- The scheme of the metal door is made taking into account the fact that between the jamb and the base there should be a small gap (about 15 - 20 mm). It is called mounting.It allows, firstly, to correctly set the frame, adjust its position, and secondly, to additionally insulate the perimeter opening.

- The hinges on the door are placed at an equal distance from each other, and their number is determined by the mass of the canvas, with its light weight, two canopies are enough. But in any case, their distance (upper and lower) from the sections of the sash is selected about 150 mm (for openings of standard height).

Materials and accessories are being prepared. When working with iron, welding is required. Plus, a punch (electric drill with a chipper) and a “grinder”. Everything else is an ordinary household tool, square, tape measure. With materials a little more complicated, you have to choose.

- For the frame, corners or profiles are suitable (with a side of 4 cm). Here it is worth focusing on the purpose of the structure, the requirements for its stability and the option for further finishing. If high-quality insulation, increased strength are assumed, then a door from a profile pipe is the best solution. But stiffeners can be made from the corner.

- The frame sheathing is made of sheet steel. It is necessary to optimally combine indicators such as the total mass of the canvas and its strength. But in any case, the use of metal with a thickness of less than 2 mm is not recommended.

- Fasteners. Any iron door, even home-made, even purchased, in the opening is fixed with anchor bolts. An exception is only for models mounted in wooden (frame) buildings. As a rule, when you independently install the doors at their entrance, they are attached to special frames or to the base by welding or large hardware.

Everything else - gaskets, heat-insulating and finishing materials, fasteners, accessories - at the discretion of the master.

With a lack of experience in the manufacture of steel doors with your own hands, it is better to limit yourself to overhead hinges. Canopies of a hidden type are much more difficult to install, and a professional approach is needed here.

Box

There are no problems with it, but on condition that all measurements and cutting of the blanks are done correctly, in strict accordance with the drawing up. It is easy to weld the individual parts into a single structure of the correct geometry. It is only necessary to carry out work on a perfectly flat, hard surface and constantly monitor the angles. At the end of the assembly of the joint, all the seams are carefully ground with a diamond disc.

Without fail, hinges and fixing strips with drilled holes are welded to the box. With the help of the last details, it is fixed on the wall from any material.

Features of wood of various species

When manufacturing wooden doors, you need to know the advantages and disadvantages of the material. The final result depends on it. The main difference between wood is its hardness. Soft woods are easily processed, but less resistant to moisture. Such material is suitable for interior doors. Hard wood is difficult to handle with a hand tool, but the material is more resistant to moisture. Such wood is suitable for the manufacture of entrance doors.

Speaking of wood species, it is worth considering the resinousness of the material. Larch takes first place in this regard. The product from it will stand in damp for a long time. Resin protects against rot.

The following requirements are set for the selection of boards:

- minimum number of knots

- wood moisture no more than 15%,

- perfect evenness.

For outbuildings, used material taken from the dismantling of old buildings is suitable. Beautiful doors to the house are best made from a new board.

Hardwood

- Birch quite hard and difficult to process, but has an attractive texture.

- Beech characterized by increased strength, but is deformed when humidity changes.

- Alder soft and rots quickly in high humidity.

- Oak solid, tends to crack, but is resistant to moisture and beautiful.

- Nut It has an interesting texture, can be easily processed, is not afraid of moisture and mechanical stress.

- Maple moderately hard, not bad to process, medium resists dampness.

For the manufacture of entrance wooden doors are often used oak or beech.

Conifers

- Of conifers, it is considered the most popular Pine. Soft wood is easily processed, but poorly resists moisture. The material is best used in the manufacture of wooden interior doors.

- Larch It is characterized by a beautiful texture and high resinity. Hardwood is highly resistant to moisture, which allows the use of a board to assemble entrance doors.

- Spruce knotty, lighter and softer than pine, slightly inferior in strength to it.

Tools

In production, special machines are used for the manufacture of wooden doors.

- Reysmus necessary for processing boards. The most productive are two-sided planing machines that clean the workpiece in one pass.

- Without millingthe machine making wooden doors is not possible. With its help, lock joints are made on the boards, chamfers are selected, and shaped blanks are processed.

- When gluing on a wooden frame linings used press.

- Circularsaw dissolve the board to the desired size.

Nobody will buy expensive machine tools to make wooden interior doors with their own hands at home. An electric board is suitable for opening the board disksaw.

You can select grooves and process the surface of the workpieces hand milling.

Additionally, you must have at hand:

- drill,

- screwdriver

- wood hacksaw

- grinder

- chisels, mallet, corner, level, tape measure.

For painting the door leaf, it is advisable to use a compressor with an air gun.

Necessary materials

To make a wooden door with your own hands you will need the following materials:

- dry sheet pile

- self-tapping screws

- wood glue.

At the time of purchase, the thickness of the boards is selected taking into account the installation location of the door leaf. For the interior sash, wood with a thickness of 25 mm is sufficient. A 50 mm thick board is used for the front door. After the acquisition, it is advisable to dry the wooden blanks by laying them on a flat surface using linings.

Additionally, a mortise lock, hinges, handles, a peephole are bought at the entrance wooden door. For the interior casement, it is enough to take the hinges and the handle with the latch.

How to make a wooden door?

Assembling a simple wooden door with your own hands, a drawing, a complex scheme is not needed. It is enough to measure the height and width of the door leaf. The dimensions of the sash are calculated so that it fits into the grooves of the door frame, and a gap of about 5 mm remains around the perimeter. In the manufacture of a wooden door, the main elements are prepared: a tongue-and-groove board with a thorn-groove lock for the blade and cross-member from edged blanks.

The step-by-step instruction for assembling a wooden door with your own hands consists of the following steps:

- boards are cut along the height of the future canvas and laid out on a flat surface in compliance with one direction of the pattern of annual rings,

- spikes with grooves are lubricated with carpentry glue, connect all the boards, tightly squeezing the canvas with a clamp,

- after the glue has dried on the end strip, a spike is cut from the end of the product, and the entire surface of the shield is milled and polished.

- To prevent the sash from falling apart, the structure is fastened with cross members. The edged board is shaped like a trapezoid, grooves are made on the canvas to a depth of 1/3 of the thickness of the wooden workpiece and lubricated with wood glue. The crossbars are inserted into the recesses, tapping with a mallet. For reliability, you can fix it with self-tapping screws.

- In order for the sash to last longer, antiseptic treatment is performed. If it is necessary to install a double-glazed window on a wooden door, a window is cut out in a shield with a jigsaw. In the center of the end face of the entire perimeter of the opening, a board is beaten - an emphasis for two glasses. After installing a double-glazed window, the edges are framed with a glazing bead or a decorative strip.

If necessary, a thick canvas, the sash is made of two layers. In the two-layer technology of manufacturing a wooden door, the boards of both panels are perpendicular. Glue them together with wood glue.

Keyway

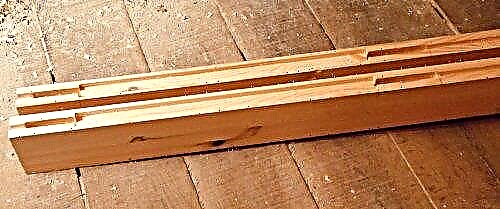

You can assemble warm wooden doors for a private house without much effort from boards with keys. Manufacturing technology consists of the following steps:

- Boards are cut along the length of the door leaf.

- A shield is folded from the blanks on a flat table, temporarily fastened with two jumpers.

- The cutter for the strut with dowels is cut with a milling cutter or a planer.

- From a bar with a section of 40x40 mm, a brace and dowels are cut, rounding the outer part of the workpieces.

- Details are inserted into the grooves of the door leaf, screwed with furniture bolts or self-tapping screws.

- Temporary jumpers are removed.

- The assembled leaf is subjected to grinding, impregnation with an antiseptic, and painting.

Usually, massive doors are made of oak, beech or cedar to enter a house. The canvas can be decorate antique or give it a modern style. A simple wooden door, assembled with your own hands from a pine board, is suitable in a bathhouse or barn.

Shield

A panel door is a budget option. The frame is a rectangular frame from the board. Fibreboard sheets are glued on both sides. In industrial conditions, additional veneer or laminate cladding is used. Another design feature of the door is filling the voids of the frame with a heater from woodworking waste: sawdust, shavings, small chips, corrugated cardboard.

Let's consider how to make a shield wooden door from the boards with your own hands step by step:

- according to the size of the sash, a fiberboard sheet is cut out, as well as blanks from the boards for the frame,

- all elements are laid out on a flat surface, connecting together with wood glue and self-tapping screws,

- the bottom shield of fiberboard with a wooden frame formed voids that are covered with sawdust,

- the upper part of the frame is greased with glue, a second shield made of fiberboard is laid and the entire sash is pressed with a press.

On the finished door leaf, veneer can be glued on top as a finish, and round off sharp corners with a milling cutter.

Paneled

The design of paneled doors is a frame made of timber, inside which a set of horizontal cross members, vertical lintels, and also mediators are inserted. As a result, cells are formed for inserting the panel. The technology allows you to make a wooden door with glass, plastic, and other material. The strength of the web depends on the number of crossbars.

- At home, in the manufacture of the frame, two racks are cut, the upper, lower and castle cross, as well as the upper and lower middle.

- The edges of the timber must be milled and grooves for inserting the panel.

- At the ends of the crossbars, connecting spikes are cut, and at the end of the grooves are for inserting the center pieces and panels.

- Bottom and top of the uprights cut the grooves for the castle connection with the spikes of the cross members.

- All elements of the frame are connected with thorn-groove locks, lubricated with carpentry glue.

- Using a wooden mallet, tap each joint for a tight connection.

The panel is cut so large that it fits into the cell with a gap of 2 mm. Glass inserts or fiberboard immediately fasten with glazing beads. The edges of a thick plywood or chipboard panel are milled until they are 2 mm thinner than the grooves cut on the frame. The last fastening framing glazing bead.

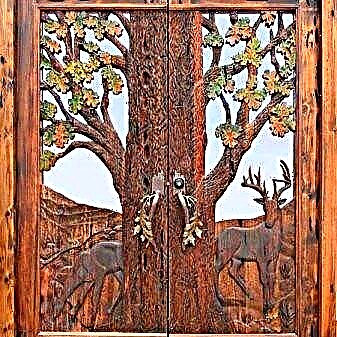

Decor

Decorating a homemade wooden door begins with polishing. Further processing is an antiseptic that protects wood from moisture and pests. After drying, the door surface is covered with two layers of primer or putty. The top coat is paint or varnish.

If there is a professional tool, as well as certain skills, the canvas is decorated with carvings, cut out stencils and even make a mosaic.

Features and models

Entrance doors are installed both in the apartment and in the private house. Regardless of the location of this design, its direct purpose is considered to be reliable protection of housing from cold, noise and burglary. Therefore, choosing this or that model of an entrance door it is necessary to consider many nuances. Recently, home-made structures made of metal and wood have been very popular, while metal doors are distinguished by their functionality and design features, they are resistant to explosions, break-ins, fireproof and bulletproof.

As for the wooden options, they are characterized by an original aesthetic appearance, doors with sliding systems also deserve special attention.

Today, there are many types of entrance doors. According to their purpose, they are:

- Fireproof and bulletproof. Such products are made of metal of increased strength. In addition, these types of doors are additionally treated with reinforcing compounds.

- Shockproof. They are the most reliable option to protect your home.

- Soundproof Prevent noise and sounds from entering the house.

- Sealed. Often installed in farm buildings.

Entrance doors can open in many ways. There are swing and sliding models of structures. In addition, the doors are classified by the number of leaves and there are:

- Single leaf. Made from a single piece of canvas.

- One and a half. They are a two-piece structure where only one opens.

- Bivalve. Large doors with two opening wings.

All entrance doors differ in appearance and shape, therefore, they distinguish between rectangular and arched products. Deaf transom designs are also popular.

Recently, manufacturers have been trying to make the entrance to housing unusual, so they often decorate doors with glass.

Door leaf

- The manufacturing technique of the frame is absolutely identical.

- To reinforce, stiffeners are installed according to the selected scheme.

- The groove for the lock tongue is cut out.

- Covering the frame on one side. It is produced by the method of fastening by welding steel sheets, with a small overflow. In the hinge area of about 5 mm, the length of the frame is about 10 - 15. It is recommended to “clutch” the lining with several seams, not exceeding 40 mm. To ensure the reliability of fastening, the intervals between adjacent sections are selected within 20.

- Depending on the scheme, at this stage of assembling the metal door, the fastening elements of the lock are installed, hinges are welded (those parts that are attached to the canvas) and a window for the eye is cut out.

- If the sash is supposed to be insulated, then immediately the heat-insulating material is laid, it is placed between the stiffeners, which prevents its subsidence under its own weight.

- It remains to weld the second sheet of metal on the wrong side of the frame and also cut a hole for the eye and the lock cylinder in it.

- The last thing to do with the sash is to carry out a check of its geometry and polish all the joints, welds and paint with soil to prevent metal corrosion.

If the “one and a half” scheme is selected, then all technological operations for a small canvas are absolutely identical, with the exception of the eye and the door lock. But the upper and lower stops, for fixing in a stationary position, should be provided.

Finish finish

Making a metal door with your own hands is not all. It is necessary to issue it accordingly. With the blocks installed in the utility buildings, it is quite simple, as a rule, they are painted. But if we are talking about the door at the entrance to a residential building (apartment), then it is desirable to decorate it. The choice of option is at the discretion of the owner, and some recommendations will help in this.

How can I finish the canvas:

- Solid materials - multilayer plywood, fiberboard, vinyl plastic, wooden paneling, laminate, MDF, followed by varnish (colorless or with tinting components).

- To tighten the sash used dermatin, leather.

- The door on the water to the apartment can be pasted over with decorative film. Since the impact of atmospheric factors is minimal, such a finish will last a long time. And given the low cost and ease of design - one of the best solutions.

Assembly assembly

In fact, it all comes down to hanging the sash, checking its position, working constipation and adjusting (if necessary). It remains only to install the handle, lock and peephole. If in the door scheme there are bolts, lower (upper) stops, then you need to make markings.

The shutter is covered, and places of drilling holes are marked on the jamb. After readiness, their coincidence with the locking elements is controlled. This applies to both the main canvas and the additional, small.

The final “touch” is the installation of the manufactured door in the opening and the lubrication of all rubbing parts (which many forget about). After that, we can state that everything is complete.

For those who have metal working skills and want to get a high-quality iron door at low cost, self-production is the best option. Moreover, the drawing, the scheme, the external finish are chosen not by the manufacturer, but by the master. And this means that the entrance to the house will not only be securely protected, but also originally designed, and the block structure will fit perfectly into the interior of a particular building.

Materials

Entrance doors are made from various raw materials, while most often they use metal and natural wood for independent production. It is worth noting that the functional properties of the structure will depend on the selected material, since a good and high-quality door should not let in cold air and completely isolates the house from extraneous sounds.

Despite the fact that metal products are very popular, still wood does not lose its advantages and is often used in the manufacture of doors. Such models are found both in modern apartments and in country houses. As a rule, such wooden structures are made from solid oak, as well as from birch and pine. Doors made of wood do excellent insulation and retain heat well.

Due to the unique characteristics of wood, products from boards protect the house from the penetration of cold air flows.

In order for such products to not rot and mold during operation, they are additionally treated with special solutions that reliably protect the canvas from wood pests and increase the service life. In addition, the tree is easy to process and decorate with various inserts or carvings. The only disadvantage of this raw material is its high cost, so plywood panels are often used as an alternative.

Unlike wood, metal structures have more advantages. They are strong and durable, and in order for such products to provide optimal insulation, they are covered with a protective layer. Metal doors are also painted with enamels and varnish, this protects their surface from rust and allows for installation both indoors and outdoors in country houses.

For the independent manufacture of input structures, as a rule, steel sheets are chosen.

Recently, you can also meet plastic or metal-plastic doors. They are intended for buildings where there is the possibility of vestibule heating, because plastic does not retain heat. In addition, such products will require additional protection in the form of alarms or gratings. Although plastic is easy to install, it is still not suitable for homes.

A huge selection of colors, the presence of decorative inserts and ease of care allows the use of plastic doors to enter various organizations and offices.

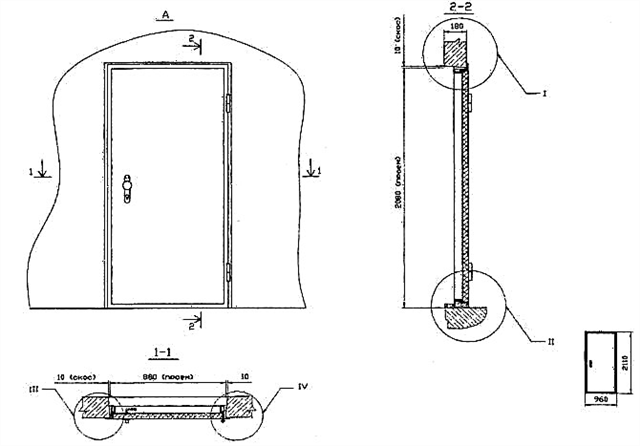

Dimensions

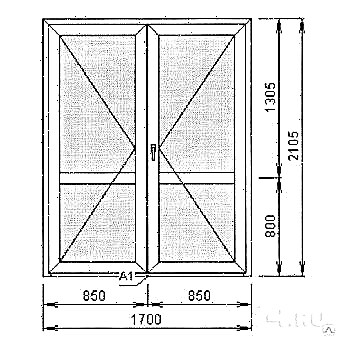

Before you begin work on the manufacture of the entrance structure, you should first determine the dimensions of the future product and correctly measure the doorway. It is worth paying attention to the fact that in each apartment or house the dimensions of the openings may vary. If you plan to install a standard single-leaf door, then for it you will need sheets of 860 × 2050 mm or 960 × 2050 mm. If necessary, custom panels can be made. For simple double-leaf doors, canvases of 1200x2050 mm or 1400x2050 mm are used, but for office rooms and private houses it is best to choose larger structures - 1500x2100 mm or even 1600x2100 mm.

Often when installing the entrance doors you have to deal with such a problem as the non-standard dimensions of the openings. The most optimal solution in this situation is to expand or bookmark the opening itself.

Step-by-step instruction

Housing repair takes a lot of time and money, so often many owners decide on a desperate step and do the finishing work with the installation of entrance doors on their own. Of course, the design can be purchased ready-made, but if you want to save money, then it is quite possible to make it yourself. Before you start making the door, you need to determine the external forms and the load that will be exerted on the product.

You will also need to prepare the following tools:

In addition, upon completion of work, the doors should be beautifully designed, so it is important to correctly measure the extensions, place the box, and decorate the doorways with platbands or additional elements.

To perform such work, you can choose a different material, but the most affordable is considered a natural tree. In order to make a quality product, preference should be given to a beam 5 mm wide and not more than 4 mm thick. Such canvases provide excellent sound insulation. In addition, in wooden doors it is easier to set a threshold and set steps. As for the installation technology, they are based on the correct measurements of the door frame; it is from them that the maximum connection of the beam with the frame will depend. And for street construction, you will also need to weld the hinges and paint the surface.

For the manufacture of a standard door, a 205 cm long web is assembled, while its width can be different. First, the frame is prepared, which will look like a frame. Then, according to the size of the frame, a fiberboard sheet is cut out and fixed with self-tapping screws. After assembling such a design, gluing of fiberboard is done. It is advisable to strengthen the bars not only with screws, but also with glue.

The finished door is carefully dried, and then the hinges are screwed and a lock is inserted. In order for the product to get an attractive look, it is recommended to additionally trim it with dermantine on the gasket. Thus, the door will turn out beautiful and insulated.

Particular attention when installing the structure must also be given to the lock frame. Its thickness should correspond to the thickness of the canvas. In addition, the lock is a thin mechanism, therefore, even 1 mm is not allowed to be mounted during its installation.

As for painting, this is the final stage of work, and it is carried out only after the box is installed.

How to insulate?

One of the purposes of the entrance structure is good thermal insulation, so the canvas should be well insulated. To do this, use various technologies. If the box is made of metal, then first of all you need to fill its internal idle cavity. In this case, it is filled with special insulating material in the form of mineral wool or foam. Also, to keep the door warm, it can be sheathed with a wooden beam. The only drawback of this technology is the formation of cold bridges.

The front door is well insulated with dermantine. With this technology, the door leaf is upholstered only on one side, and a thin layer of insulation is applied to two openings. The thermal insulation is glued directly to the door, and then it is decorated with dermantine or genuine leather.

Equally important is the protection of the structure from drafts. Two methods are used for this:

- Insulation of gaps between the box and the canvas. As a thermal insulation, a rubber or foam rubber seal is well suited. It is attached using a self-adhesive base and is applied both to the box itself and to the canvas.

- Opening the door frame. The outer and inner sides of the slopes are upholstered, and the gaps between the opening and the structure are filled with insulation material.

In the event that none of the types of thermal insulation is suitable, an alternative solution may be to install a second entrance door.

How to weld canopies?

Before you put the front door, you need to weld the hinges (awnings). As a rule, to keep the standard design, two loops will be needed, the distance between them should not exceed 20 cm. Before the work begins, the canopies are thoroughly cleaned and treated with a special solution. It is advisable to weld the hinges horizontally with respect to the door frame. In the event that the opening is already installed, then the weld is carried out vertically.

The hinges are welded as follows:

- Prepared blanks are divided into two components, one of which is welded to the canvas, and the second to the box.

- First attach the lower loop, it is seized by welding in several places.

- Checks the location of the loop using the building level.

- Final verification in progress.

As for the upper hinge, the installation work is carried out similarly, the only thing worth considering is the location of both canopies in the same plane. They should be placed clearly on top of each other. At the end of the work, it is important to clean the seams well from plaque, then weld the hardware itself.

Examples and options

No matter how wonderful a country house or apartment is, the external housing design must be complemented by a beautiful and reliable front door. To date, the construction market is represented by a wide selection of these structures, all of them differ among themselves by the production material, design and safety class.

For cozy houses in the country, you can choose both wooden and metal doors. It all depends on the exterior of the building. If, for example, the house is built of natural timber, then the door should be made of natural material. For brick buildings, metal structures are best suited. As for the apartments, for them durable metal doors are considered the best choice, capable of not only protecting housing from burglars, but also providing excellent noise and heat insulation.

See how to make a metal front door with your own hands in the next video.